The Future of Magnetic Lifting

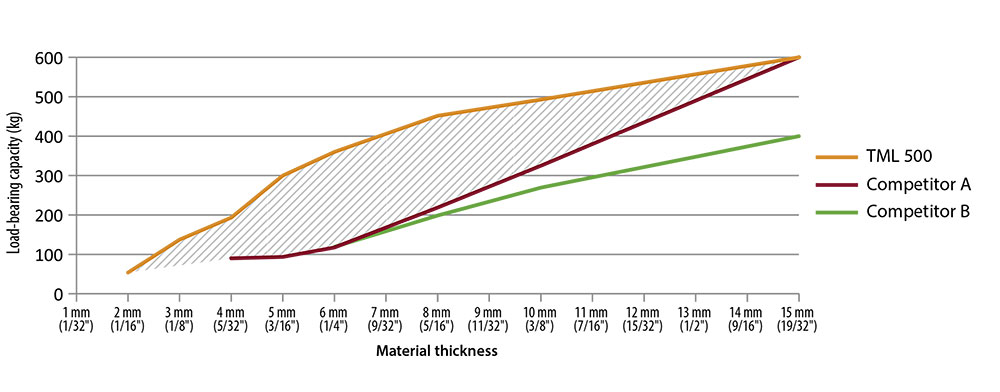

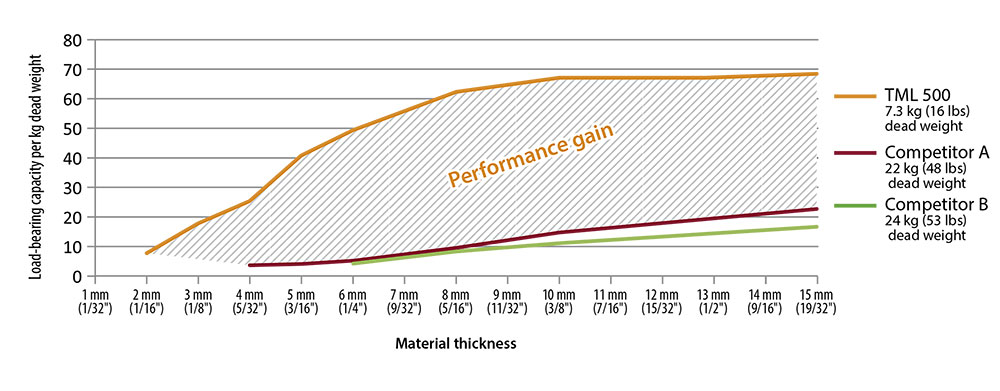

Patented technology allows magnets to be manufactured up to 70% lighter than comparable products.

Lift Smarter

Reduced Maintenance

Hardened steel bottom plate with TiN-coating eliminating the need to regrind the magnetic bottom plate.

Innovative Design

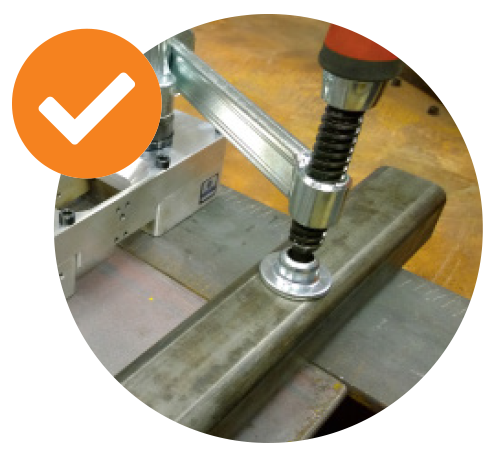

New design allows for use between the flanges of a steel beam.

Easy Positioning

Slight premagnetisation for the easy positioning of the magnet.

One-Handed Activation

Simple locking mechanism can be easily activated with one hand.

Fully Articulated

Fully flexible double swivel lifting point – 180° pivot, 360° rotation.

More Clamping Methods

Additional connection threads inside the housing allow for customisation.

Flat Material Lifting Magnets

| TMH 50 | TML100 | TML250 | TML500 | TML1000 | |

|---|---|---|---|---|---|

|  |  |  |  |

|

| Max Load Bearing Capacity | 50kg | 100kg | 250 kg | 500 kg | 1000 kg |

| Breakaway Force: | 300 kg on 6 mm steel S235 | 300 kg on 6 mm steel S235 | 750 kg on 10 mm S235 | 1,500 kg on 15 mm S235 | 3,400 kg on 12 mm steel S235 |

| Min Material Thickness: | 2 mm | 2 mm | 2 mm | 2 mm | 3 mm |

| Unit Weight: | 1.6 kg | 1.7 kg | 3.5 kg | 7.3 kg | 18 kg |

| Dimensions (LxW): | 190 x 124 mm | 146 x 124 mm | 240 x 91 mm | 266 x 118 mm | 422 x 154 mm |

Round Material Lifting Magnets

| TML 90 R | TML 400 R | |

|---|---|---|

|  |

|

| Max Load Bearing Capacity: | 90 kg* | 400 kg* |

| Pipe Diameter: | 25 - 200 mm | 50 - 400 mm |

| Breakway Force: | > 270 kg on 6 mm steel S235 | > 1,200 kg on 15 mm S235 |

| Min Material Thickness: | 2 mm | 2 mm |

| Unit Weight: | 1.8 kg | 8.2 kg |

| Dimensions (LxW): | 190 x 124 mm | 266 x 118 mm |

Fixturing/Positioning Magnets

| TMC 70 | TMC 300 | TMC 600 | TMA 600 | TMA 600 FXL | MAG-PRY 300 | |

|---|---|---|---|---|---|---|

|  |  |  |  |  |

|

| Breakaway Force: | 70 kg on 3 mm S235 steel | 300kg on 6 mm steel | 600 kg on 10 mm steel S235 | 2 x 300kg on 6 mm S235 steel | 2 x 300kg on 6 mm S235 steel | 300 kg 6 mm S235 steel |

| Min Material Thickness: | 1 mm | 2 mm | 2 mm | 2 mm | 2 mm | 2 mm |

| Unit Weight: | 0.29kg | 1 kg | 2.6 kg | 2.7 kg | 4.7 kg | 2.27 kg |

| Dimensions (LxW): | 71 x 51 mm | 83 x 80 mm | 108 x 105 mm | 162 x 124 mm | 355 x 145 mm | 139 x 564 mm |

Increased Power to Weight Ratio