ALFRA TML Lifting Magnets

Category: Lifting Magnets Tags: Lifting Magnets for Metal Sheets, Lifting Magnets for PipesALFRA TML Lifting Magnets

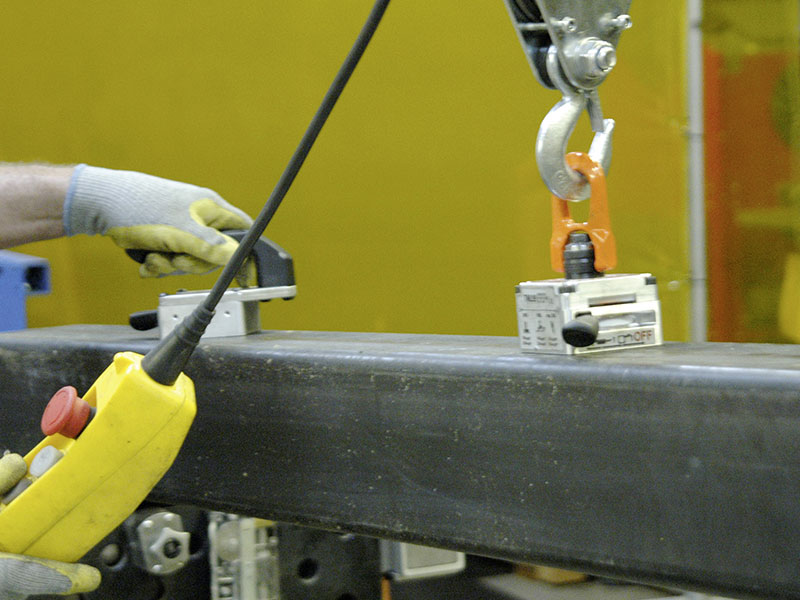

Introducing the ALFRA TML Magnetic Lifting System, a smarter way to lift, move, position, align and transport metal sheet and piped product.

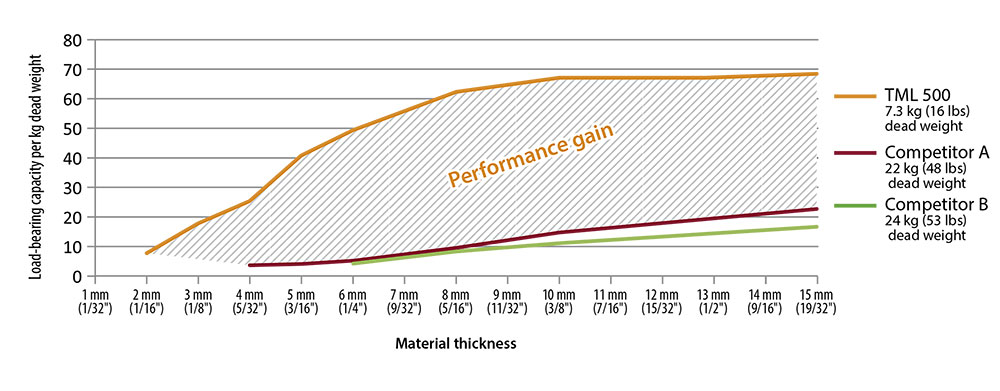

ALFRA’s patented TML technology, which stands for ‘Thin Material Lifting’, generates an enormous holding force, even on extremely thin-walled magnetic material, allowing handling of materials with a thickness as low as 2mm. Due to the higher holding forces TML produces, ALFRA is able to design and manufacture lifting magnets that weigh up to 70% less than comparable products on the market. As a result, ALFRA Lifting Magnets are much lighter and easier to handle in the workplace.

Made in Germany, ALFRA has design and manufactured industrial products for more than 100 years and has a reputation for outstanding quality and product innovation.

ALFRA TML Lifting Magnets

Category: Lifting Magnets Tags: Lifting Magnets for Metal Sheets, Lifting Magnets for PipesKey Benefits of ALFRA Lifting Magnets:

- 180° pivotable and 360°rotatable load swivel.

- Able to activate and use with one hand.

- Hardened steel bottom plate with TiN-coating eliminating the need to regrind the magnet’s bottom plate: reduced maintenance.

- Slight premagnetisation for the easy positioning of the magnet.

- Magnets can be customised thanks to additional connection threads inside the housing.

- New design allowing for the use of the magnet even between the flanges of a steel beam.

- The magnetic field concentrates directly on the material and reduces scattering losses to a minimum.

- Magnets allow welding at a distance of just 15 mm (9/16″) from the magnet‘s external side.

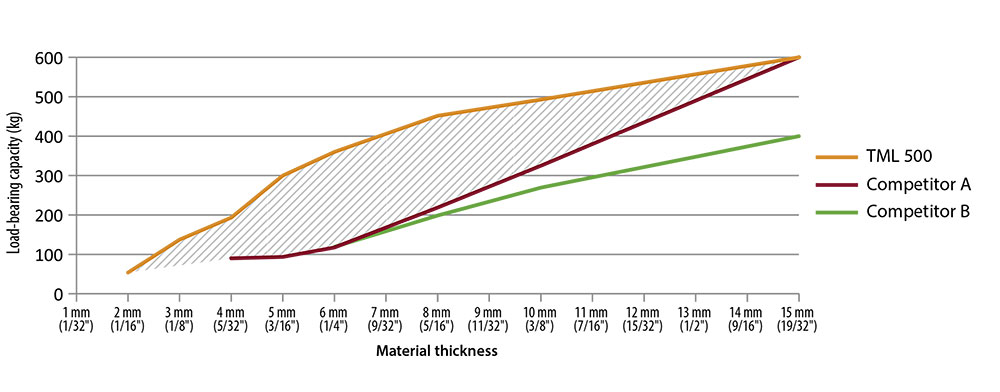

Graph A – The TML provides more performance

Graph B – Less weight but more performance

Lifting Magnets for Sheet Products

| TML100 | TML250 | TML500 | TML1000 | |

|---|---|---|---|---|

|  |  |  |

|

| Max. load-bearing capacity | 100 kg (220 lbs) | 250 kg (550 lbs) | 500 kg (1,100 lb) | 1,000 kg (2,200 lbs) |

| Breakaway force | (660 lbs) on 6 mm (1/4") steel S235 | > 750 kg (1,653 lbs) on 10 mm (3/8") steel S235 | > 1,500 kg (3,300 lbs) on 15 mm (9/16") steel S235 | > 3,400 kg (7,480 lbs) On 12 mm (1/2”) Steel S235 |

| Min. material thickness | 1 mm (1/32") | 2 mm (1/16") | 2 mm (1/16") | 2 mm (1/16") |

| Unit weight | 1.7 kg (3.7 lbs) | 3.5 kg (7.7 lbs) | 7.3 kg (16 lbs) | 18.0 kg (238 lbs) |

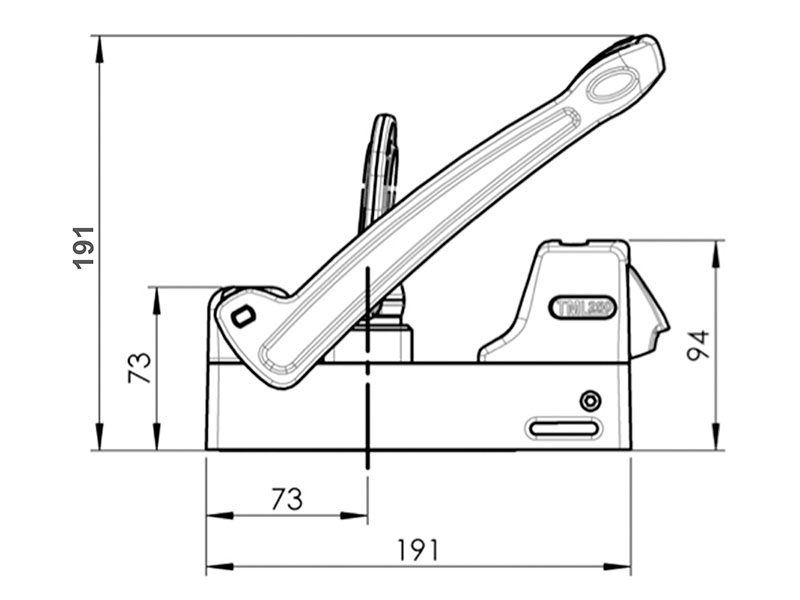

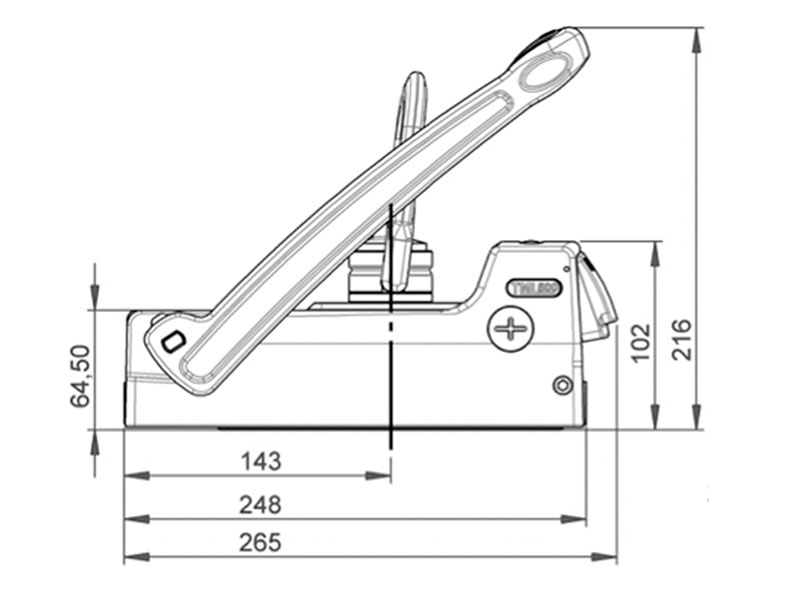

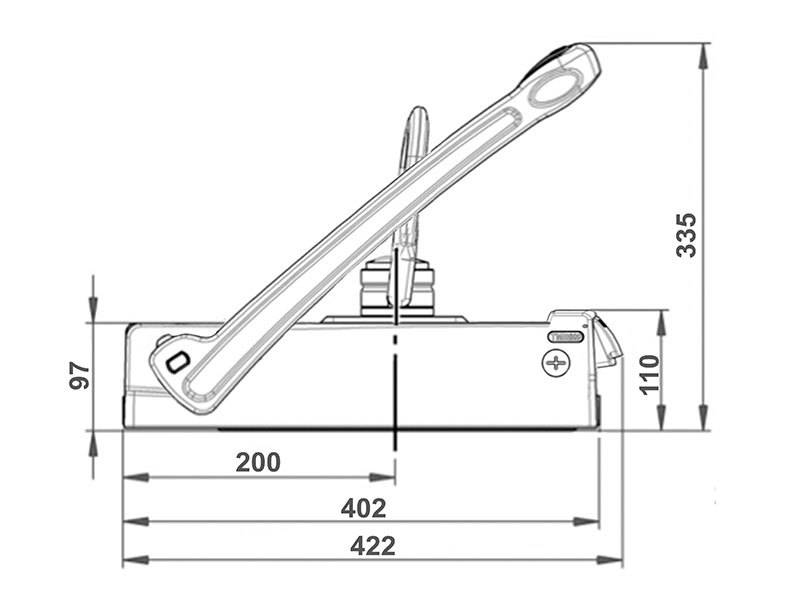

| Dimensions LxW | 82.5 x 80 mm (3-1/4" x 3-1/8") | 191 x 71 mm (7-1/2" x 2 -13/16") | 265 x 118 mm (10-7/16" x 4-5/8") | 403 x 103 mm (15-7/8" x 4-1/16") |

Lifting Magnets for Pipe Products

| TML 90 R | TML 400 R | |

|---|---|---|

|  |

|

| Pipe diameter | 25 - 200 mm (1" - 7-7/8") | 50 - 400 mm (2" - 15-3/4") |

| Max. load-bearing capacity | 90 kg* (200 lbs)* | 400 kg* (880 lbs)* |

| Breakaway force | > 270 kg (595 lbs) on 6 mm (1/4") steel S235 | > 1,200 kg (2,650 lbs) on 15 mm (9/16") S235 |

| Min. material thickness | 1 mm (1/32") | 2 mm (1/16") |

| Unit weight | 1.8 kg (4 lbs) | 8.2 kg (18 lbs) |

| Dimensions LxW | 82.5 x 80 mm (3-1/4" x 3-1/8") | 265 x 118 mm (10-7/16" x 4-5/8") |

*Max. load-bearing capacity on round pipes: 20 – 50 % of fl at material subject to pipe diameter and material thickness.